Karsten Rist

In the summer of 1959 I returned from Ann Arbor, Michigan, to Leadville, Colorado. I had just finished my first year of MBA studies at the University of Michigan. I had a summer job with the Climax Molybdenum Company to do surveying in the mountains surrounding the Climax mine.

On one of my free weekends I decided to visit my friend Bob Johnson in Colorado Springs. Bob worked for the Colorado Interstate Gas Company as IBM operator, It was his job to operate the IBM punch card machines which could sort, collate, and print punched cards. These machines could also be wired to perform calculations and supported the accounting functions in all major companies. Bob took me to see the offices where he worked and told me: “Karsten, we have this phantastic new machine which can do incredible things. It is called an IBM 650 computer.

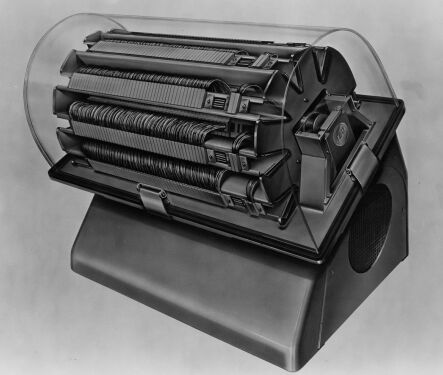

You will just go nuts when you see it!” He ushered me into a room big enough to be the office of the company president. The room was filled with the familiar looking, large, grey housings of IBM card readers, card punches, printers and other peripheral equipment. These machines had been adapted to be the input and output units of the computer. We stood on a floor which had been elevated about a foot to make room for a tangle of cables and to distribute cold air to the various pieces of equipment. This was necessary because the logic of the equipment was driven by hundreds of radio tubes. The high speed memory of the computer was contained on a drum.

I learned that instructions for the machine were placed at large intervals on the drum in hopes that the next instruction would be close to the read-write heads when it would be needed. A grey noise of humming, whirring and clacking filled the air. Bob showed me the computer itself and explained to me how it could do complex calculations in the blink of an eye and how it could chose a logical path through hundreds of instructions to solve mindboggling problems. Bob also introduced me to a mathematician who had the job of programming the machine and whom I considered a modern incarnation of Merlin the magician.

I was so impressed that I inquired about a course in computer technology upon my return to the University of Michigan. Such a course existed in the school of engineering and thanks to my mining engineering degree I was allowed to enroll. I took the course and became an instant expert. It was the only course offered on the subject of computers. When I graduated with my MBA in 1960 the Climax Molybdenum Company offered me a job which was focussed on justifying the use of a computer to support mine management. IBM had just introduced a new generation of equipment: the IBM 1401 and IBM 1620 computers. These machines used transistors not vacuum tubes and they sported core memory not the drum memory of the 650. They were unbelievably reliable, fast and powerful.

IBM supported my efforts to justify the lease of a computer for the mine with resources from all over the country. We introduced the PERT (Program Evaluation and Review Technique) scheduling system and used it successfully to organize one critical fourth of July shutdown. We did statistical studies of the ore body and the distribution of ore concentrations. The most enjoyable of all the projects was a simulation of the rail transportation system on the Storke level. Management faced the decision whether or not to construct a second tunnel to relieve what looked like unbearable train delays. The Storke tunnel was the bottleneck through which all mine trains had to travel either on their way into the mine to be loaded or on their way out of the mine to be unloaded. Our model relied on sets of actual working times, collected in the mine, which described the time it took to load and unload trains. From the two tables of data loading and unloading times items were picked at random to drive the model.

The Climax Molybdenum Company was able to lease computer time on a 1620 computer which had been installed at Kaman aircraft in Colorado Springs. It was one of the first machines to be released by IBM. It had 20,000 decimal characters of core storage, a tape reader as input and a typewriter as output. Addition and multiplication were performed by use of a table. The programming language was SPS (Symbolic Programming System): One line of code translated into one 12-digit machine instruction. My program had 400 lines of code and took over an hour to assemble, When we needed to make a change we could display the memory position to be changed and dial the new code directly into memory.

Carol and our little boy, Curtis, accompanied me to Colorado Springs whenever possible. On one of our trips together we listened to radio reports of John Glenn’s first suborbital rocket flight.

The engineers at Kaman aircraft were quite friendly and asked kiddingly how the trains were running as we struggled to debug our code. Finally the last bug was corrected. We were able to demonstrate convincingly what level of efficiency additional trains in the system could achieve. While there would be some increase in train waiting time as more trains came into use the cost of the wasted time was quite small in comparison to the cost of a second tunnel. Best of all, the model had a close connection to reality and could be explained to management in real mining world terms, It put the issue of the need for a second tunnel to rest and saved the Climax Molybdenum Company over a million dollars. It did not, however, convince management that the company needed a computer.

I was able to publish an article about our computer simulation in “Mining World”. It was a nice addition to my resume. What IBM and experience taught me about computers in general and the 1620 in particular became the foundation of my later work at Northern Natural Gas, Automatic Sprinkler and Systems Engineering.

but wait, there’s more…

(also see related article)

I had received a thorough education in computer usage and stood at the leading edge of this new technology. At the same time it became clearer day by day that Climax was not likely to install a computer in the near future. So I made the decision in 1962 to accept a job offer from Northern Natural Gas in Omaha, Nebraska, to work as an industrial engineer. While my own career advanced and demanded my full attention I lost track of what was happening in modeling and mining. That is – until I got an e-mail from Portugal many years later in 2004.

The problems and the principles of engineering work have not changed much. The tools and the sophistication of the solutions offered surely have. Thinking back I can still hear the question of the Kaman engineers: “Are the trains running yet?”.